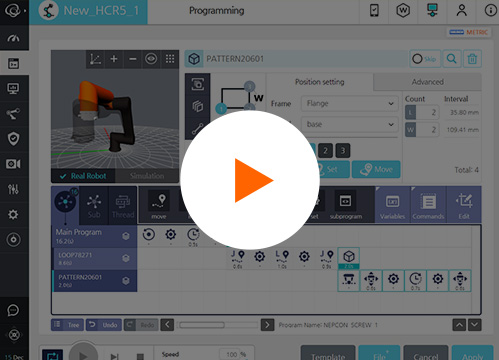

Automation is no longer difficult. The collaborative robot HCR is easy to control and is flexible in responding to changes in prod uction layout, effectively cutting investment cost and operating expenses.

It not only automates manual work but also provides a safe and convenient work environment.