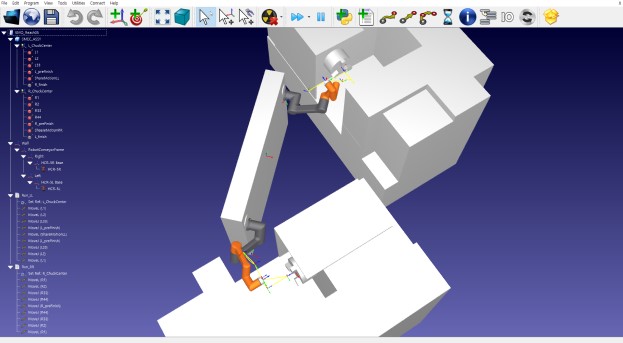

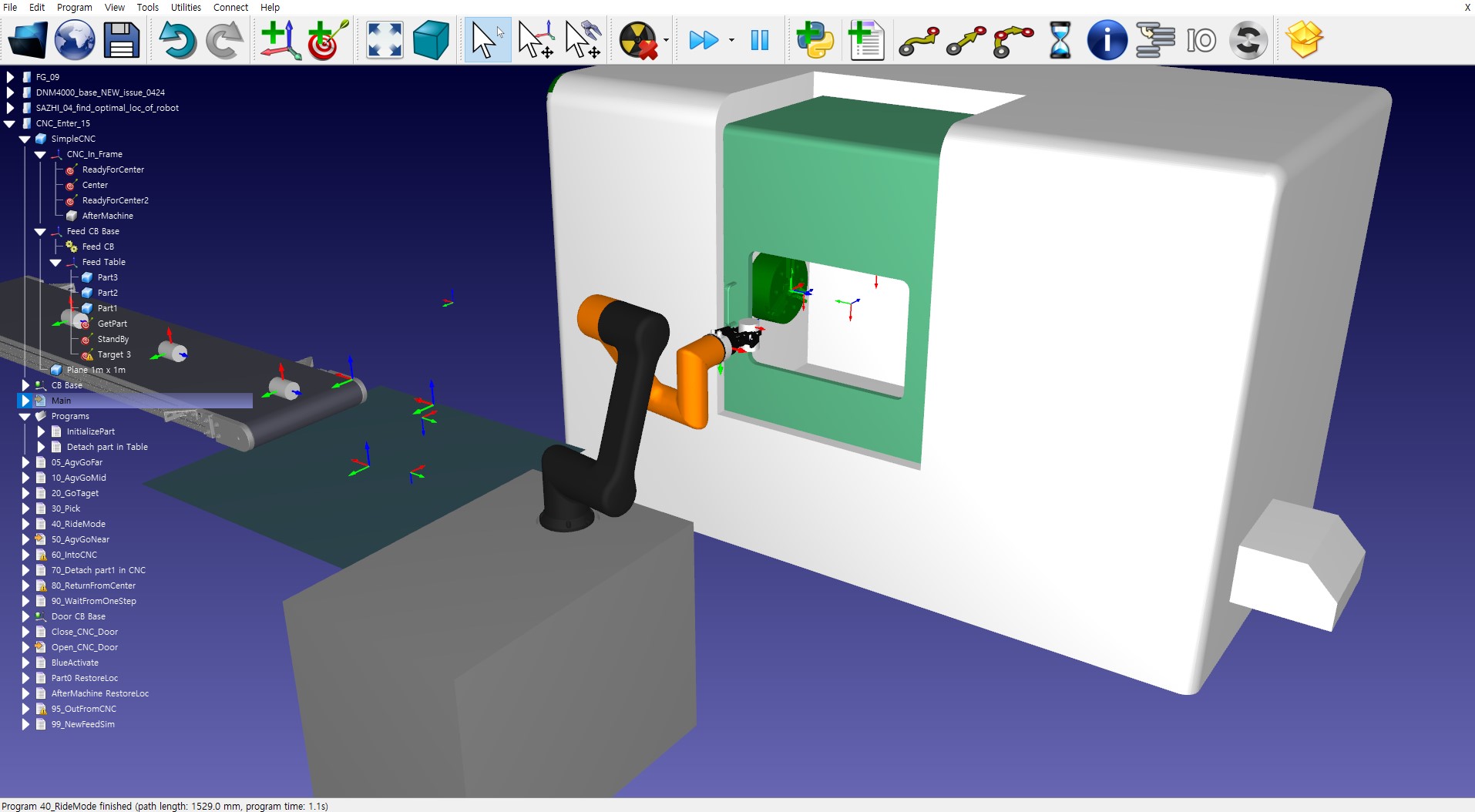

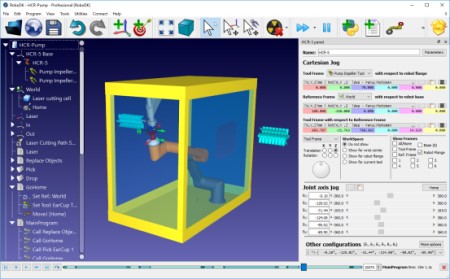

RoboDK’s simulation and offline programming tools allow you to program robots outside the production environment, eliminating production downtime caused by shop floor programming. You can easily program any Hanwha robot in a few steps from your computer.

Specifications

| Item | Value |

|---|---|

| Intuitive graphical user Interface | No programming skills are required. Program your robot with a few clicks. Easily setup your simulation using drag & drop. |

| Robot machining | Optimization tools are provided to automatically convert CAM programs to robot programs. (support for G-code and APT files). |

| Multiple robot simulation | Users can program over 500 robots, mechanisms and external axis using the same simulation environment. |

| Wide variety of applications | Including machining, painting, pick and place, 3D printing and more. |

| CAD to Path features | CAD to path features, including support for multiple CAD software. (SolidWorks, Inventor, Fusion 360, Rhino, ...) |

| Fast curve and fast surface | Allows offline programming for many applications such as welding, deburring, cutting and more. |

| Cycle time calculation | Calculate and optimize cycle time. |

| Robot Calibration | Robot calibration tools available to improve robot accuracy. |

| Cost-effective solution | Different software packages and pricing based on customers needs. |

Compatibility

| Item | Status |

|---|---|

| Compatible Robot | HCR-3, HCR-5, HCR-12 |

| PC OS | Windows, Mac, Linux, Android, iOS, Raspberry Pi |

| 3D format | STEP, IGES, STL |

| Machining Programs | G-code, APT, NC files |

| Plug-ins | SolidWorks, Mastercam, Rhino, Inventor, Fusion 360, FeatureCAM |

| API | Python, C#, Visual Basic, C , Matlab |

- Previous

- | ATI Axia80 Force/Torque Sensor Kit

- Next

- | Gecko Gripper